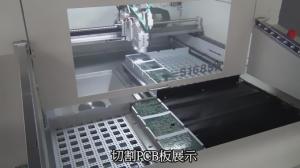

60000rpm 350 X350 Mm High-Definition Visual Alignment Automatic

Offline PCB Depaneling Router

Off- line pcb depaneling router Basic specifications

01. X, Y cutting speed: 0 ~100mm/s

02. Machine Repeat Accuracy: ± 0.01mm

03. X, Y1,Y2 ,Z Control Methods: Industrial IPC and PC

04. X, Y1,Y2 ,Z Drive Mode: AC Fiber Optic Servo Motor

05. Machine Operation and Data Storage: PC System

06. Cutting accuracy: ± 0.05mm

07. Spindle speed: Max 60000rpm

08. Host voltage: 220V 1ψ 50 / 60HZ

09. Air pressure supply: above 4.5kg/cm2

10. Power Consumption: 1.8KVA

11. Dust Collection: Lower Dust Collection (Standard) or Upper Dust

Collection

12. Dust collector voltage: 220V (380V) 3ψ

13. Upper dust collector size: L650*W400*H1350mm

14. Dust collector size: L665*W635*H1650mm

| Working size | Working Area | 350 X350 mm ( Customizable large size) |

| PCB Thickness | 0.3~3.5mm |

Hardware brand | Waste collection methods | Dust collection box |

| Dust collection method | Upper or Lower Vacuum |

| Dust collection box parameters | Upper vacuum 2HP-3HP/Lower vacuum 3HP-5HP |

| Sensor Switch Brand | Panasonic Japan |

| Servo motor brand | Panasonic Japan |

| Electrostatic ion wind gun brand | Taiwan |

| Guideway Brand | Taiwan PMI |

| Screw brand | Taiwan TBI grinding grade |

| CCD camera brand | Germany BASLER |

| Spindle Brand | Japan NAKANISHI |

| Computer host brand | ASUS brand host |

| Machine weight | 840KG |

| Security grating | Taiwan |

Electric | Power supply | AC220/380V50/60HZ three-phase |

| Compressed air | 0.4-0.6 MPA (with filter) |

Operation control | Operating System | Chinese/English Optional |

| Software control method | PC+ Industrial Control System Control |

| Programming methods | Computer programming, AOI scanning and editing programs faster and

more accurate |

| Warning light | Three-color sound and light alarm (normal work, waiting for test,

fault alarm) |

| With fault alarm: air pressure instability, blocking, collision |

Safe production | Produce order mode production, four-level password protection

(automatic, manual, sensor protection, etc.) |

Technical Parameters | Statistics function | Both left and right board with statistics function |

| Information management function | Support MES information system to seamlessly connect equipment and

information management, Open Ethernet Interface, and supports

TCP/IP network communication protocol, and necessary related

software and programs; Open the BAR CODE function port. |

| X.Y, Z, axis drive | Servo motor + screw, guide rail |

| Worktable input and output methods | Servo motor + screw, guide rail |

| Cutting product requirements | Left and right worktables can separate different products at the

same time |

| Cutting height requirements | Left and right worktables can separate different heights and

products at the same time |

| MARK point identification requirements | MARK points of different shapes can be identified, and MARK points

can be freely set before each division. |

| LED aperture requirements | LED aperture brightness can be adjusted in software |

| Camera | Software controlled camera moves up and down |

| PCB positioning and adjustment methods | Universal fixture, positioning PIN, tool fixture |

| Milling cutter diameter range | 0.8-3.0mm |

| Milling cutter management | The software can automatically adjust the height according to the

thickness of the PCB board and the toughness length of the cutter

to extend the service life of the cutter and standard tool

detection. |

| MES docking | Open MES docking port function |

| BAR CODE scan | Open BAR CODE Scan Port Function |

| Cutting speed | 0-100mm/S adjustable per second |

| Working table | two worktables |

| Cutting function | Can cut straight, curved, L-shaped, U-shaped |

| Trouble shooting | Software can detect failure points, have I/O port detection

capabilities, and have detailed alerts |

Service | Machine warranty 15 months. Our after-sales points are Suzhou,

Dongguan, the United States, Brazil, Britain, France, and Turkey.

Welcome to be our foreign agent. |

Double Y-axis workbench structure, the left and right workbenches

are driven by servo motors and screw guides; the left and right

workbenches can split different products at the same time, and the

left and right workbenches can split different products at the same

time, with different heights; it can meet small batches Production,

avoid excessive repetitive actions and waste of replacing jigs,

fast processing speed, high production efficiency, strong

stability, greatly improve processing.

The double Y-axis worktable PCB pick-up area is equipped with

grating safety facilities, and there is a transparent protective

cover during the cutting process to avoid accidental injury to the

operator by the broken knife and flying knife, and double

protection for the personal safety of the operator.

1. The high-speed imported main shaft is used to cut and split the

board, which greatly reduces the cutting stress, with high

precision, low inertia and fast response.

2. Milling cutter detection system, real-time monitoring of the

state of the milling cutter, effectively preventing the continued

operation after the cutter is broken, etc.

3. Brand-new vision system, uniform ring light source, with

brightness adjustment function, making various types of Mark points

better recognized, suitable for plating Tin, gold-plated,

copper-plated, tin-sprayed and various PCBs of different colors are

equipped with visual alignment compensation functions.

4. The software can automatically adjust the height according to

the thickness of the PCB and the toughness of the milling cutter to

extend the service life of the milling cutter.

Equipped with upper and lower dust suction devices, using

electrostatic brushes to seal the cutting points, and independently

vacuum for single cutting points, greatly improving the dust

suction effect.