Hunan Xinghuai New Material Technology Co.,Ltd was established on May 14, 2021 with a registered capital of 1.36

billion RMB and a land area of 300 acres. It is jointly funded and

constructed by Huaihua High-tech Industry Investment and

Development Group Co., Ltd., Huaihua Water Investment Group Co.,

Ltd. and Chongqing Zhongpu New Material Technology Research

Institute Co., Ltd.. With 70% of the state-owned capital, making it

a state-holding enterprise.

Chiyan Glass is an environmentally friendly cover glass brand founded by Zhaohong Precision (Beijing) Technology Co., Ltd. The products include "CHUM" four series of original glass products:

Chiyan-C series - Crystal-Ceramic Glass

Chiyan-H series - High Aluminosilicate Glass

Chiyan-U series - UTG Ultra-Thin Flexible Glass

Chiyan-M series - Medium Aluminosilicate glass

Currently our High-end display cover glass is mainly used in

consumer electronics fields such as mobile phones, tablets,

laptops, car navigation, instruments, and smart homes, as well as

in special fields such as high-speed rail, aviation, and

photoelectricity, etc.

As a production base of Chiyan Glass -Hunan Xinghuai New Materials Co., Ltd. has an independently

developed and designed melting workshop. From melting to finished

products, there are 18 processes. The self-designed glass melting

furnace and melting process are used to effectively solve the

problem of bubble elimination and highly improve the quality of the

products.

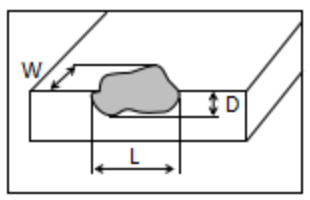

Xinghuai independently developed the "Similar to Thinner"

Technology to control the thickness of glass difference within 0.01

mm, which is far exceeding the domestic average.

The automatic correction and balancing technology of the glass

ribbon we developed can perfectly make the glass ribbon run in the

tin bath, effectively reduce the occurrence of defects, and greatly

improve the yield of finished products.

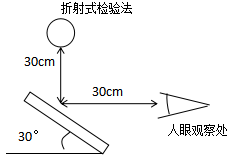

We also have the most advanced Green Cutting System, which can cut

the glass into appropriate sheet perfectly. And we also adopts

the world's most advanced Isla Testing Eequipment to inspect the

quality, which can automatically inspect every single glass sheet

to ensure the quality.

Due to the maturity of our technical team, we have received many

honorary qualifications, such as:

National High-tech Enterprise, Hunan Provincial Specialized and New

Small and Medium-sized Enterprises, National Outstanding Enterprise

in the Electronic Information Industry, First Prize in the National

Innovation and Entrepreneurship Competition, etc.

And also we have

passed ISO9001/14001/45001/RoHs/REACH/Sb/Halogen

free/IATF16949 certificates etc.

We are looking forward to be your sincerely long term original

glass partner.