High-Viscosity Filling Machine Various Water Agent, Emulsion, Oil

Suspension, Suspension Agent High Viscosity Materials

CCG5000-6D-type intelligent high-viscosity filling machine

General information:

CCG5000-6D type intelligent high viscosity filling machine is

suitable for the packaging of various water agent, emulsion, oil

suspension, suspension agent and high viscosity materials. The

whole machine is inline structure, using servo motor drive and

volume measurement and filling principle to realize the high

precision of filling dose. PLC control, touch human-machine

interface, convenient operation.

Technical parameters:

| 1 | Production capacity | 1,000 ml Bottle ≤ 1,200 bottles / h 5000ml bottle ≤ 600 bottles / h (With water as the medium, the actual production capacity

fluctuates up and down depending on the customer material) |

| 2 | Adapto bottle type | Round bottle: Φ80-140mm in diameter Bottle height is 140-340mm Square flat bottle: 80-200mm wide 80-140mm wide 140-340mm high |

| 3 | Fill capacity | 1000-5000mL. |

| 4 | Measurement accuracy | ± 5g (1000mL) ± 8g (5000mL) |

| 5 | Feed port height | 2400mm. |

| 6 | Feed port diameter | DN40. |

| 7 | Outer diameter of the lower feeding mouth | Φ26mm. |

| 8 | Corresponding to the minimum barrel mouth inner diameter | ≥ Φ30mm. |

| 9 | Air source pressure | 0.6-0.8MPa. |

| 10 | Power Supply / Power | ~380V 50Hz/2.2KW. |

| 11 | Overall dimensions | 2000 × 1110 × 2600mm (L × W × H) |

| 12 | Weight | Approximately 1,600 Kg |

| 13 | Weight feedback is optional, maximum range 6Kg, if the material

proportion ≥ 1.2 is customized according to the actual situation |

Equipment dimension drawing:

Equipment advantages:

1, is widely used in the automatic filling and production of 1-5L

bottles in pesticides, fine chemical, daily chemical, fertilizers,

oils and other industries.

2, Jinwang adopts PLC programming and control, servo motor drive

synchronous belt with + drive stable double-wire bar lifting

mechanism, which ensures the high precision of piston movement

travel and realizes accurate filling.The synchronous belt with

embedded metal wire will not break. At present, foreign first-class

packaging manufacturers adopt this structure. Compared with similar

products on the market, the ordinary motor + encoder is used, after

the chain drive structure for a long time, the chain has a tensile

nature, affecting the filling accuracy and equipment stability.

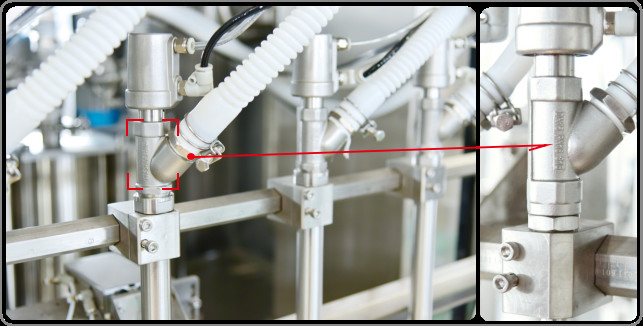

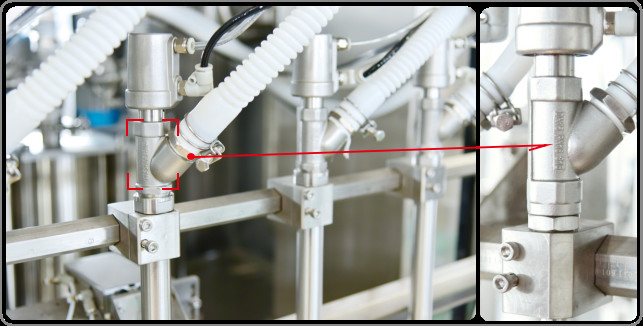

3, adopts integral cast filling head of 316, good molding and

longer service life. Use tetrafluoror hose with good corrosion

resistance for highly corrosive materials.

4,'s latest tetrafluorocarbon technology improved wear resistance,

extended service life and reduced maintenance costs.

5,The whole machine adopts high quality SUS304 stainless steel,

better adapted to the filling and production environment. Good

anti-corrosion performance and easy for cleaning. Outoutsourced

stainless steel and tempered glass door cover seal the body, and

the exhaust outlet (nozzle aperture is Φ120mm diameter) can be

connected to the factory air introduction system to discharge the

exhaust gas from the filling process.

6, complete electric control system adopts French Schneider

configuration and integrated electric control system, which is more

stable and reliable, safe, green and low energy consumption.

7, filling machine is short of bottles, and the filling machine and

the rear side are equipped with coordinated photoelectric. When the

bottle is not blocked, it automatically realizes the linkage

function with the rear equipment.

Main configuration of the equipment:

| No ial |

First name "Said that." |

Brand name |

| 1 | Programmable controller CPU. | Schneider. Schneider |

| 2 | Touch-screen | Schneider. Schneider |

| 3 | Converconverter | Schneider. Schneider |

| 4 | Servo system | Schneider. Schneider |

| 5 | Count photoelectric | SICK. Schker |

| 6 | Close proximity switch | LEUZE. Labor measurement |

| 7 | Switch on the power supply | Schneider. Schneider |

| 8 | Pressure switch | SMC. |

| 9 | Cylinder | FTEC. Eptai |

| 10 | Solenoid valve | FTEC. Eptai |

| 11 | Button | Schneider. Schneider |

| 12 | Warning lamp | Schneider. Schneider |

| 13 | Circuit breaker | Schneider. Schneider |