Upper Weighing Type Filling Machine Packaging Of Better Liquid And

Foam Materials Inline Structure Convenient And Intuit

CZS-6B-type upper weighing type filling machine

General information:

CZS-6B upper weighing filling machine is the latest generation of

improved upper weighing filling machine, suitable for the packaging

of better liquid and foam materials such as water, emulsion and

oil. The whole machine is inline structure, with PLC control, touch

human-machine interface, convenient and intuitive operation.

Technical parameters:

| 1 | Fill speed | ≤ 1300 Boals / h (1L) ≤ 1000 Boals / h (4L) (* Water as medium) |

| 2 | Measurement accuracy | ± 0.2-0.5% (* Water as the medium) |

| 3 | Bottle type | Round bottle —— diameter Φ80-140mm Bottle height is 140-340mm —— long 80-200mm wide 80-140mm High, 140-340mm |

| 4 | Fill range | 1-4L. |

| 5 | Feed pipe diameter | Dn40. |

| 6 | Feed port height | 3450mm. |

| 7 | Air source pressure | 0.6-0.8MPa. |

| 8 | Power Supply / Power | ~380V 50Hz/2.0KW. |

| 9 | Overall dimensions | 2700 × 1700 × 3570mm (L × W × H) |

| 10 | Weight | About 2,000 Kg |

Main configuration of the equipment:

| No ial | First name "Said that." | Brand name |

1 |

Weing sensor | METTLER TOLEDO. Mettololedo |

2 | Programmable controller CPU. | Schneider. Schneider |

| 3 | Touch-screen | Schneider. Schneider |

| 4 | Converconverter | Schneider. Schneider |

| 5 | Count photoelectric | Sick. Schker |

| 6 | Close proximity switch | Leuze. Labor measurement |

| 7 | Switch on the power supply | Schneider. Schneider |

| 8 | Pressure switch | SMC. |

| 9 | Cylinder | FTEC. Eptai |

| 10 | Solenoid valve | FTEC. Eptai |

| 11 | Button | Schneider. Schneider |

| 12 | Warning lamp | Schneider. Schneider |

| 13 | Circuit breaker | Schneider. Schneider |

Equipment dimension drawing:

Equipment advantages:

1,The complete electric control system of adopts French Schneider

configuration and integrated electric control system, which is more

stable and reliable, safe and low energy consumption, 20% lower

energy consumption than other brands.

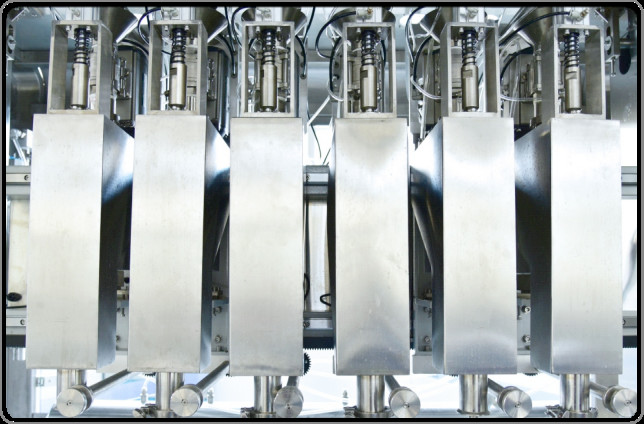

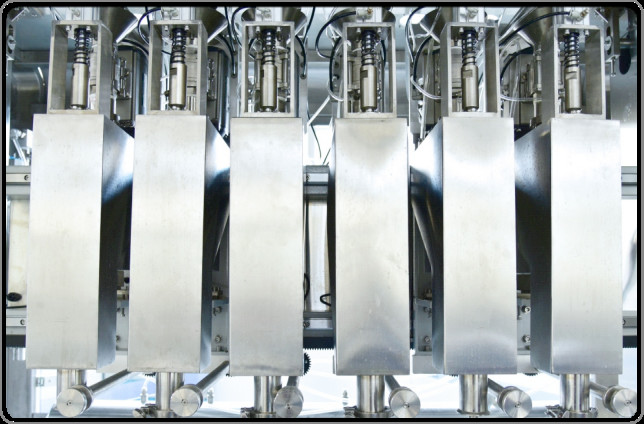

2, high accuracy: Each filling head is equipped with an independent

weighing and filling system (Mettler-Toledo METTLER TOLEDO Weight

Sensor, USA) to ensure the high accuracy of filling measurement.

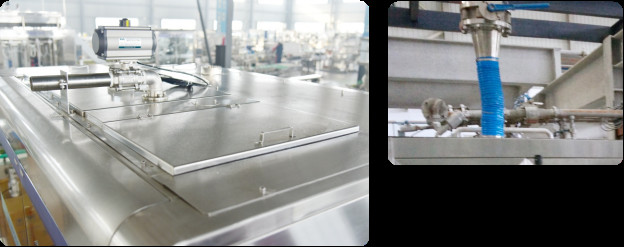

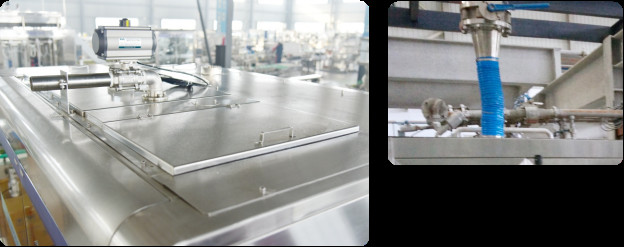

3,The whole machine consists from a total feeding box to 6

separation boxes, which is weighed and filled, with high capacity,

(greatly improved compared with the weighing and filling method)

4, The filling head cylinder adopts the multi-segment type, which

can realize the size change of the filling volume and improve the

accuracy.

5, separate air storage tanks ensure the stability of equipment

operation.

6, The whole machine adopts high-quality SUS304 stainless steel,

with good anti-corrosion performance and easy to clean.

Outoutsourced stainless steel and tempered glass door cover seal

the body, and the exhaust outlet (nozzle aperture is Φ120mm

diameter) can be connected to the factory air introduction system

to discharge the exhaust gas from the filling process.