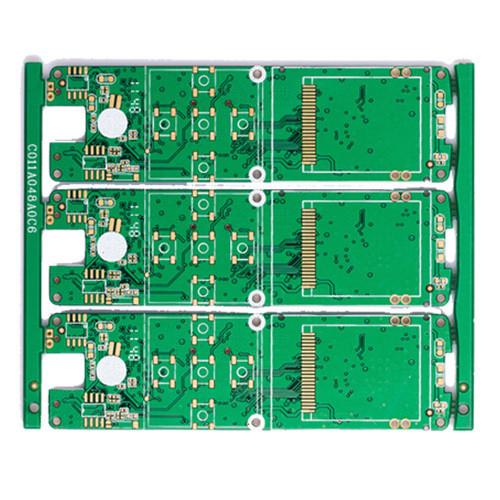

Fr4 Copper Clad Laminate Multilayer HDI 1.0mm PCB For Mobile Phone

Quick detail:

Material:Fr4 |

Layer:4 |

Surface finish:immersion gold |

Copper weight:1oz |

Board size:4.5*3cm |

Total thickness:1.6mm |

Min line width and space:3mil |

Min hole: 0.15mm |

Name:High density Interconnector printed circuit boards |

HDI PCB information:

HDI is an abbreviation of High Density Interconnector . It is a

kind of circuit board which uses micro blind buried hole

technology. HDI is a compact product designed for small-capacity

users.

Microvias are used as the interconnects between layers in high

density interconnect (HDI) substrates and printed circuit boards

(PCBs) to accommodate the high input/output (I/O) density of

advanced packages. Driven by portability and wireless

communications, the electronics industry strives to produce

affordable, light, and reliable products with increased

functionality. At the electronic component level, this translates

to components with increased I/Os with smaller footprint areas

(e.g. flip-chip packages, chip-scale packages, and direct chip

attachments), and on the printed circuit board and package

substrate level, to the use of high density interconnects (HDIs)

(e.g. finer lines and spaces, and smaller vias).

IPC standards define microvias as blind or buried vias with a

diameter equal to or less than 150 μm. With the advent of

smartphones and hand-held electronic devices, microvias have

evolved from single-level to stacked microvias that cross over

multiple HDI layers. Sequential build-up (SBU) technology is used

to fabricate HDI boards. The HDI layers are usually built up from a

traditionally manufactured double-sided core board or multilayer

PCB. The HDI layers are built on both sides of the traditional PCB

one by one with microvias. The SBU process consists of several

steps: layer lamination, via formation, via metallization, and via

filling. There are multiple choices of materials and/or

technologies for each step.

Microvias can be filled with different materials and

processes:filled with epoxy resin (b-stage) during a sequential

lamination process step; filled with non-conductive or conductive

material other than copper as a separate processing step; plated

closed with electroplated copper; screen printed closed with a

copper paste. Buried microvias are required to be filled, while

blind microvias on the external layers usually do not have any fill

requirements.A stacked microvia is usually filled with

electroplated copper to make electrical interconnections between

multiple HDI layers and provide structural support for the outer

level(s) of the microvia or for a component mounted on the

outermost copper pad.

HDI PCB application:

Electronic design continues to improve the performance of the

whole, while also trying to reduce its size. From mobile phones to

smart weapons, small portable products, "small" is always the same

pursuit. High-density integration (HDI) technology can make the end

product design more compact, while meeting the electronic

performance and efficiency of higher standards. HDI is widely used

in mobile phones, digital cameras, MP3, MP4, computers, automotive

electronics and other digital products, among which the most widely

used mobile phones. HDI board generally used to build-up

manufacturing, the more the number of layers, the higher the

technical grade plate. Ordinary HDI board is basically a laminated,

high-level HDI with 2 or more layers of technology, while using

stacked holes, electroplating fill, laser drilling and other

advanced direct PCB technology. High-end HDI board is mainly used

in 3G mobile phones, advanced digital cameras, IC board and so on.

Advantages of HDI PCB:

Can reduce the cost of PCB

Increased Line Density: Interconnecting Traditional Boards to Parts

With better electrical performance and signal correctness

Reliability is better

Can improve the thermal properties

Can improve the radio frequency interference / electromagnetic

interference / electrostatic discharge (RFI / EMI / ESD)

Increase design efficiency

Parameter technology of HDI PCB:

Feature | Technical specification |

Number of layers | 4 – 22 layers standard, 30 layers advanced |

Technology highlights | Multilayer boards with a higher connection pad density than

standard boards, with finer lines/spaces, smaller via holes and

capture pads allowing microvias to only penetrate select layers and

also be placed in surface pads. |

HDI builds | 1+N+1, 2+N+2, 3+N+3,4+N+4, any layer in R&D |

Materials | FR4 standard, FR4 high performance, Halogen free FR4, Rogers |

Delivery | DHL,Fedex,UPS |

Copper weights (finished) | 18um – 70um |

Minimum track and gap | 0.075mm / 0.075mm |

PCB thickness | 0.40mm – 3.20mm |

Maxmimum dimensions | 610mm x 450mm; dependant upon laser drilling machine |

Surface finishes available | OSP, ENIG, Immersion tin, Immersion silver, Electrolytic gold, Gold

fingers |

Minimum mechanical drill | 0.15mm |

Minimum laser drill | 0.10mm standard, 0.075mm advanced |

FR4 PCBs are known for their excellent thermal stability, high

mechanical strength, and resistance to moisture and chemicals.

These properties make them suitable for a wide range of

applications, including consumer electronics, telecommunications,

automotive, industrial equipment, and more.

The FR4 material consists of a thin layer of copper foil laminated

onto a substrate made of woven fiberglass cloth impregnated with

epoxy resin. The copper layer is etched to create the desired

circuit pattern, and the remaining copper traces provide the

electrical connections between components.

The FR4 substrate offers good dimensional stability, which is

important for maintaining the integrity of the circuitry over a

wide range of temperatures. It also has low electrical

conductivity, which helps prevent short circuits between adjacent

traces.

In addition to its electrical properties, FR4 has good flame

retardant properties due to the presence of halogenated compounds

in the epoxy resin. This makes FR4 PCBs suitable for applications

where fire safety is a concern.

Overall, FR4 PCBs are widely used in the electronics industry due

to their excellent combination of electrical performance,

mechanical strength, thermal stability, and flame retardancy.