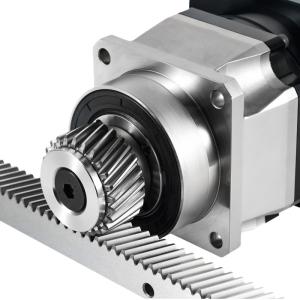

Double Shaft Inline Planetary Reducer Low Backlash Planetary Gearing For Robotics

Planetary gearbox also known as a planetary gear system or epicyclic gear train, is a type of gear mechanism consisting of one or more outer gears (planet gears) revolving around a central (sun) gear. Typically, these systems also include a ring gear (annulus) that meshes with the planet gears. The planet gears are mounted on a movable carrier which also connects to the output shaft of the gearbox.

Key Features of Planetary Reducer

- High Torque Density Planetary reducers can transmit large amounts of torque relative to their size, making them highly efficient.

- Compact Size Due to their design, planetary reducers can achieve high power transmission in a relatively small package.

- High Efficiency They typically have high efficiency and reliability, especially in applications requiring high reduction ratios.

- Load Distribution The load is distributed among multiple planet gears, which allows for higher torque transfer and reduces wear on individual gears.

- Versatility Planetary reducers can be used in various configurations, such as reducing speed or increasing torque in a wide range of mechanical applications.

Working Principle of Planetary Reducer

The planetary reducer system works by distributing the input power among the sun gear, planet gears, and ring gear. Here’s how it typically functions:

- The sun gear receives the input power and transmits it to the planet gears.

- The planet gears rotate around their own axes and also revolve around the sun gear.

- The planet gears are held in place by the carrier, which rotates and provides the output.

- The ring gear remains stationary or rotates, depending on the design and application, and meshes with the planet gears to maintain alignment and proper gear ratios.

| Specification | Segment number | Ratio | ND047 | NDS064 | ND064 | NDS090 | ND090 | NDV110 | NDV140 | NDV200 | NDV255 | NDV285 |

| Rated output torque | Nm | single | 4 | 22 | 45 | 45 | 110 | 130 | 280 | 560 | 1100 | 2200 | 3600 |

| 5 | 25 | 55 | 55 | 145 | 160 | 340 | 610 | 1300 | 2200 | 3300 |

| 7 | 20 | 48 | 48 | 125 | 130 | 300 | 560 | 1200 | 2000 | 2900 |

| 8 | — | — | — | 95 | 100 | 250 | 550 | 1100 | 1700 | 2850 |

| 10 | 15 | 40 | 40 | 95 | 100 | 220 | 460 | 950 | 1400 | 1900 |

| double | 16 | 22 | 45 | 45 | 110 | 130 | 280 | 560 | 1100 | 2200 | 3600 |

| 20 | 22 | 45 | 45 | 110 | 130 | 280 | 560 | 1100 | 2000 | 3600 |

| 25 | 25 | 60 | 60 | 145 | 160 | 350 | 610 | 1300 | 2200 | 3300 |

| 30 | — | — | — | — | — | — | — | — | — | 3100 |

| 35 | 20 | 50 | 50 | 125 | 140 | 310 | 560 | 1200 | 1200 | 3000 |

| 40 | 18 | 50 | 50 | 110 | 120 | 280 | 560 | 1200 | 1800 | — |

| 50 | 18 | 55 | 55 | 145 | 160 | 340 | 610 | 1300 | 2000 | 3300 |

| 60 | — | — | 48 | 125 | 120 | 300 | 560 | 1200 | 1800 | 2900 |

| 70 | 18 | — | 48 | 125 | 120 | 300 | 560 | 1100 | 1800 | 2900 |

| 80 | — | — | — | 95 | 100 | — | — | — | — | — |

| 90 | — | — | 40 | 95 | 100 | 250 | 460 | 950 | 1500 | 2200 |

| 100 | 15 | — | 40 | 95 | 100 | 220 | 460 | 950 | 1400 | 1900 |

| Rotary inertia | Kg.cm3 | single | 4 | 0.03 | 0.14 | 0.14 | 0.14 | 0.51 | 2.87 | 7.54 | 25.03 | 54.37 | 283.94 |

| 5 | 0.03 | 0.13 | 0.13 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | 264.41 |

| 7 | 0.03 | 0.13 | 0.13 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | 250.11 |

| 8 | — | — | — | — | 0.45 | 2.62 | 7.14 | 22.48 | 50.84 | 245.35 |

| 10 | 0.03 | 0.13 | 0.13 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 50.56 | 241.30 |

| double | 16 | 0.03 | 0.03 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 25.03 | 54.37 |

| 20 | 0.03 | 0.03 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 25.03 | 54.37 |

| 25 | 0.03 | 0.03 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 25.03 | 54.37 |

| 30 | — | — | — | — | — | — | — | — | — | 54.37 |

| 35 | 0.03 | 0.03 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 25.03 | 54.37 |

| 40 | 0.03 | 0.03 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 25.03 | — |

| 50 | 0.03 | 0.03 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 25.03 | 54.37 |

| 60 | — | — | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.48 | 50.56 |

| 70 | 0.03 | — | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.48 | 50.56 |

| 80 | — | — | — | — | 0.13 | — | — | — | — | — |

| 90 | — | — | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.48 | 50.56 |

| 100 | 0.03 | — | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.48 | 50.56 |

| Parameters Table | Segment number | Ratio | ND047 | NDS064 | ND064 | NDS090 | ND090 | NDV110 | NDV140 | NDV200 | NDV255 | NDV285 |

| Max acceleration torque | Nm | 1,2 | 1.8 times rated output torque |

| Emergency stop torque | Nm | 1,2 | 3 times rated output torque |

| Rated input speed | rmp | 1 | 4~10 | 5000 | 5000 | 5000 | 4000 | 4000 | 4000 | 3000 | 3000 | 2200 | 2000 |

| 2 | 16~100 | 5000 | 5000 | 5000 | 4000 | 4000 | 4000 | 3000 | 3000 | 3000 | 2200 |

| Max input speed | rmp | 1 | 4~10 | 10000 | 10000 | 10000 | 8000 | 8000 | 8000 | 6000 | 6000 | 4000 | 3500 |

| 2 | 16~100 | 10000 | 10000 | 10000 | 8000 | 8000 | 8000 | 6000 | 6000 | 4000 | 3500 |

| Ultraprecise backlash | arcmin | 1 | 4~10 | — | — | — | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 16~100 | — | — | — | — | — | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| Precise backlash | arcmin | 1 | 4~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 16~100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| Standard backlash | arcmin | 1 | 4~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| 2 | 16~100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 |

| Orsional rigidity | Nm/arcmin | 1,2 | 4~100 | 7 | 10 | 13 | 23 | 31 | 95 | 183 | 529 | 1030 | 1421 |

| Max. radial Force | N | 1,2 | 4~100 | 1040 | 1700 | 2300 | 3800 | 4100 | 9400 | 15000 | 25600 | 42000 | 58000 |

| Max. axial Force | N | 1,2 | 4~100 | 690 | 850 | 1055 | 1900 | 2980 | 5600 | 9300 | 19000 | 33400 | 59000 |

| Tilting moment | Nm | 1,2 | 4~100 | 55 | 65 | 94 | 106 | 198 | 482 | 1090 | 4030 | 6100 | 8500 |

| Service Life | hr | 1,2 | 16~100 | 20000hr(continuous operation 10000hr) |

| Efficiency | % | 1 | 4~10 | ≥97% |

| % | 2 | 16~100 | ≥94% |

| Weight | kg | 1 | 4~10 | 0.7 | 1.2 | 1.2 | 1.2 | 3.0 | 5.6 | 11.9 | 31.6 | 56.1 | 99.6 |

| kg | 2 | 16~100 | 1.0 | 1.6 | 1.6 | 1.6 | 3.7 | 7.3 | 15.9 | 36.9 | 70.0 | 124.5 |

| Operating Temperature | ℃ | 1,2 | 4~100 | -30℃-90℃ |

| Lubrication | | 1,2 | 4~100 | Synthetic grease |

| Protection Class | | 1,2 | 4~100 | IP65 |

| Mounting Position | | 1,2 | 4~100 | Any direction |

| Noise Level (N1=3000rpm,Non-Loaded) | dB(A) | 1 | 4~100 | ≤56 | ≤58 | ≤58 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 | ≤73 |

| 2 | 16~100 | ≤56 | ≤58 | ≤58 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 | ≤73 |

Suzhou Giant Precision Industry Co., Ltd.

Suzhou Giant Precision Industry Co., Ltd. is a

technical-service enterprise specializing in keeping on researching

core technologies and developing high precision transmission

products. We mainly provide strain wave reducers, RV reducers,

rotary actuator, planetary reducers, electric grippers.

Currently, our products have been widely used in a variety of

industrial sectors, such as manipulator, industrial robots, CNC

machine tool, printing equipment, textile machine, packaging

machinery, non-standard automation, medical equipment, laser

cutting, welding, automobile manufacturing, satellite

communications, metal processing, pharmaceutical industry, etc.

Our mission is to adhere to our service philosophy, put customer

value in our first place, to provide high-quality products,

professional technical support and diverse services.