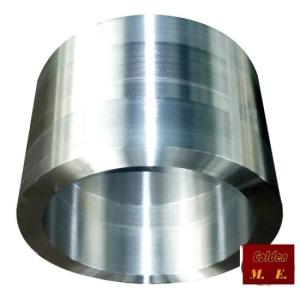

Sae1045 Sae4140 SCM415 34CrNiMo6 Forging Steel Roll Rings, Steel

Seamless Ring Forging

We are the leading manufacturer of heavy forging steel parts, our

business is custom fabrication forging by customer's drawings and

technical requirement. We are the member of " Confederation of

Chinese Metal forming Industry".

Forging products mainly includes Forged Roller,Forged Bar, Forged

Hollow Bar, Forged Steel Ring, Forged Round Disc, Forged Shaft,

Forged Module, Pipe Die Forging, Forged Stabilizer,etc

We are able to provide complete machining services such as boring,

milling, turning, grinding,welding and fabrication.Usually we make

it according to your drawing or requirements.

Process: EAF + LF + VD + Forged + Heat Treatment (optional)

Delivery Condition: Hot forged +Rough machined (black surface after Q/T)+ Turned

(optional)

Technical Data: Chemical Composition, Physical Properties and Mechanical Testing.

Test: Ultrasonic test according to SEP 1921-84 3C/c.

Standard: GB, AISI, ASTM, DIN, JIS, BS, etc.

Quality Management Certification: ISO 9001:2008

Materials:

According to customers' demands,we are available of stainless

steels, carbon steels, alloy steels, alloy tool steels, AISI316L,

AISI304L, 1.4432, 1.4462, 1.4301, 1.4404, F51, 25CrMo4, 42CrMo4,

16MnCr5, Ck45, P280GH, 40Cr, 17CrNiMo6, 34CrNiMo6, ST52-3,

S355J2G3, S355JR ,40CrNiMo, Sae8620 etc.

Manufacturing ways: Roll forged, rough turned, heat treated, CNC

turned, milled, drilled, threaded, grinded.

Heat treatment:Annealing, Normalizing, Quenching+Tempering(Q+T),

Hardening, etc.

Size: From 50mm to 5,000mm.

Weight: From 5kg/pc to 10,000kg/pc.

| Item | Process | Facility |

Inspection items

| Standard |

01 | Steel material

inspection | | Chemical composition

(EF+LF+VD) | Material standard |

| surface | Ingot inspection

specification |

| Ingot type and weight | Material standard |

| 02 | Material

store | | Division put | warehouse management |

| 1 | Heat | Heat furnace | Temperature/Time | Heating process

specification

Forging production

procedure |

|

2

↓ | Forging | Press | Reduction ratio,forging

temperature,deformation,

Surface and dimensions | Forging process card

Forging procedure |

3

↓ | Heat treatment | heat treatment

furnace | heat treatment charts | 1st heat-treatment card

Forging procedure |

|

4

↓ | Rough

inspection | | Dimensions, apperance,

Mark | Inspection specification

Forging procedure |

|

5

↓ | Rough UT | UT equipment | Single defect, concentrated

Defects bottom wave

attenuation | UT standard or

customer's technical

requirements |

6

↓ | Saw cutting | Saw machine | Dimension | IQC and forging |

7

↓ | rough turning | turning-lathe | Dimension,appearance | Rough machining

drawing |

8

↓ | UT | UT equipment | Single defect, concentrated

defects bottom wave attenuation | UT standard or

customer's technical

requirements |

9

↓ | Q+T

heat treatment | heat treatment

furnace | heat treatment charts | Heating process

specification |

10

↓ | Sampling or machining | machining tool | rough machining drawing

sampling drawing | sample machining

drawing |

11

↓ | mechanical

property test | tensile testing machine/

impact testing machine | ambient temperature,humidity,

Test temp.Sample dimension,

test method | Standard

technical specification |

12

↓ | finish

machining | machining

tool | Dimension,appearance | finish machining drawing |

13

↓ | UT | UT equipment | Single defect, concentrated

Defects bottom wave

attenuation | UT standard or

customer's technical

requirements |

14

↓ | MT | MT equipment | Magnetic particle

indication | Test standard or

Technical requirements |

15

↓ | Mark | Steel seal | marking content | Product standard

Technical requirements

Forging process |

16

↓ | Final

inspection | | Appearance, dimension, mark

acceptance inspection | Product inspection

specification

Product standard

P.O. |

| 17 | Protection/

package | Blasting

Blasting equipment | appearance

coating thickness | Product standard

Technical requirements |

Quality Control:

1: On line inspection, we perform 100% on line inspection during

production not to release any problem during production.

2: 100% inspection on each finished products.

3: Customer's own inspection.

4: Third party inspection.

5: UT( Ultrasonic Testing), MT, X-ray test, Spectrometer, Tensile

strength, Impact test machine, Hardness tester

Superiority

1. We had already passed the authentification by the ISO9001-2008,

and established a completed set of quality assurance system.

2. Under such a complete set of quality assurance systems, there is

a complete set of regulations for ordering, order handling, quality

design, purchasing raw materials, working out production plan,

production, test and inspection, packaging, storage, delivering,

etc.

3. We also have a complete set of equipment and techniques for

testing and controlling the performance of the forging products,

which ensures

Forging Process and Inspection

Packing and Delivery