R-Responsibility P-Products S-Service

sale the right products instead of the expensive one

Rps-sonic, consisted with a couple of young people who love

ultrasonic very much.The founding members of RPS-SONIC have an

average degree of Bachelor's degree or above. They have been in the

ultrasonic industry for more than 5 years and have rich experience

in ultrasound. The company's business philosophy is: Do not blindly

promote any product, find the right product for the customer. So

before each order, we will confirm all the details, including

application details, equipment conditions, equipment specific

information.

And we have the Professional import and export company, HangZhou LanBen Trade Co.,

Ltd, can export to any country wordwide.

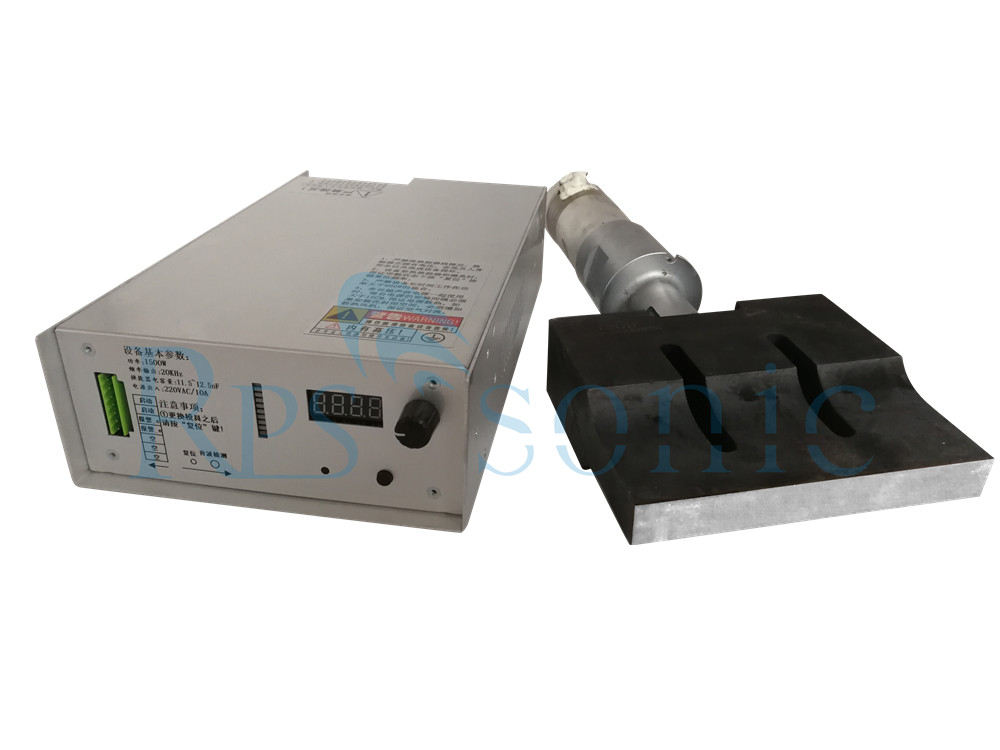

Before year 2012, we only sale second branson / dukane / rinco /

herrman/telsonic welding equipment , during these twenty year

develop, we find, more and more people have problem with the core

part of ultrasonic welding equipment -generator and transducer, so

we decided to start our business of transducer and generator of our

own transducer and generator. Many of the end user meet the

transducer problem, they don’t know why transducer broken, and

changing the expensive transducer one by one. Actually, one branson

/dukane /rinco transducer can use 10~30 year, even the cheapest

transducer can use about 5 years. So there must some reasons if

your transducer broken in one year. That’s why we want build

Rps-sonic, we need to help more end user to know more about

transducer , to use ultrasonic equipment better, to save cost when

meet problem.

The same to generator, Unreasonable operation may shorter the

use-life of ultrasonic generator. So we have to make technical

inquiry before operate ultrasonic welding machine. The key point of

ultrasonic machine is resonance, only keep every part in resonance

can make the system in best work environment.

Till now , we still have a lot of Branson /dukane/ rinco/ herrman

telsonic welding machine, so that we can confirm every

transducer/generator we made can matching to the original machine.

Of course we can make the transducer/generator replace for Branson

/dukane/ rinco/ herrman telsonic welding machine, we can also make

transducer/generator for any application of your ultrasonic

equipment. We supply OEM service for oversea customers, we already

have OEM customer in USA and German.

If you have any problem in ultrasonic area, welcome contact

Rps-sonic.