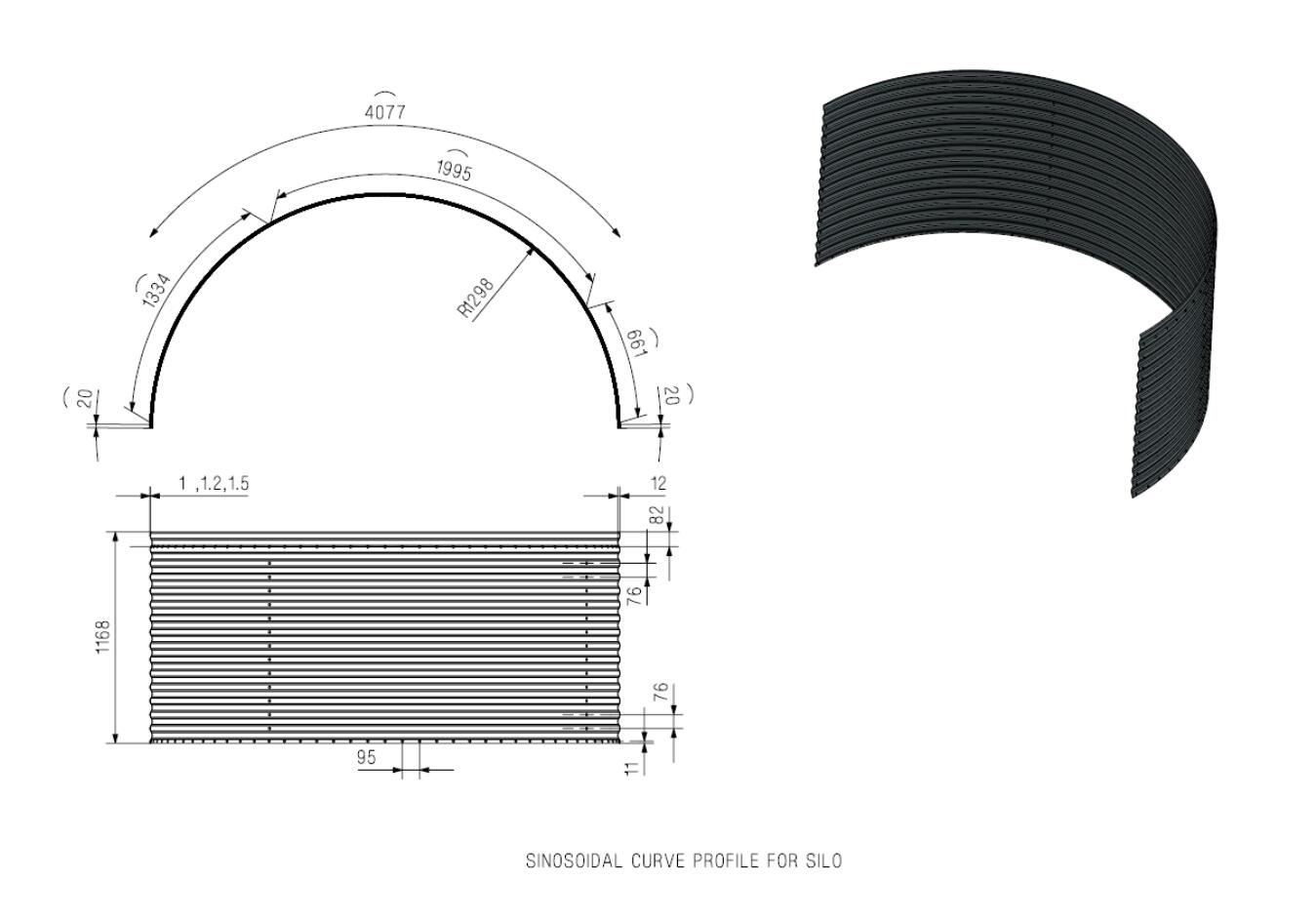

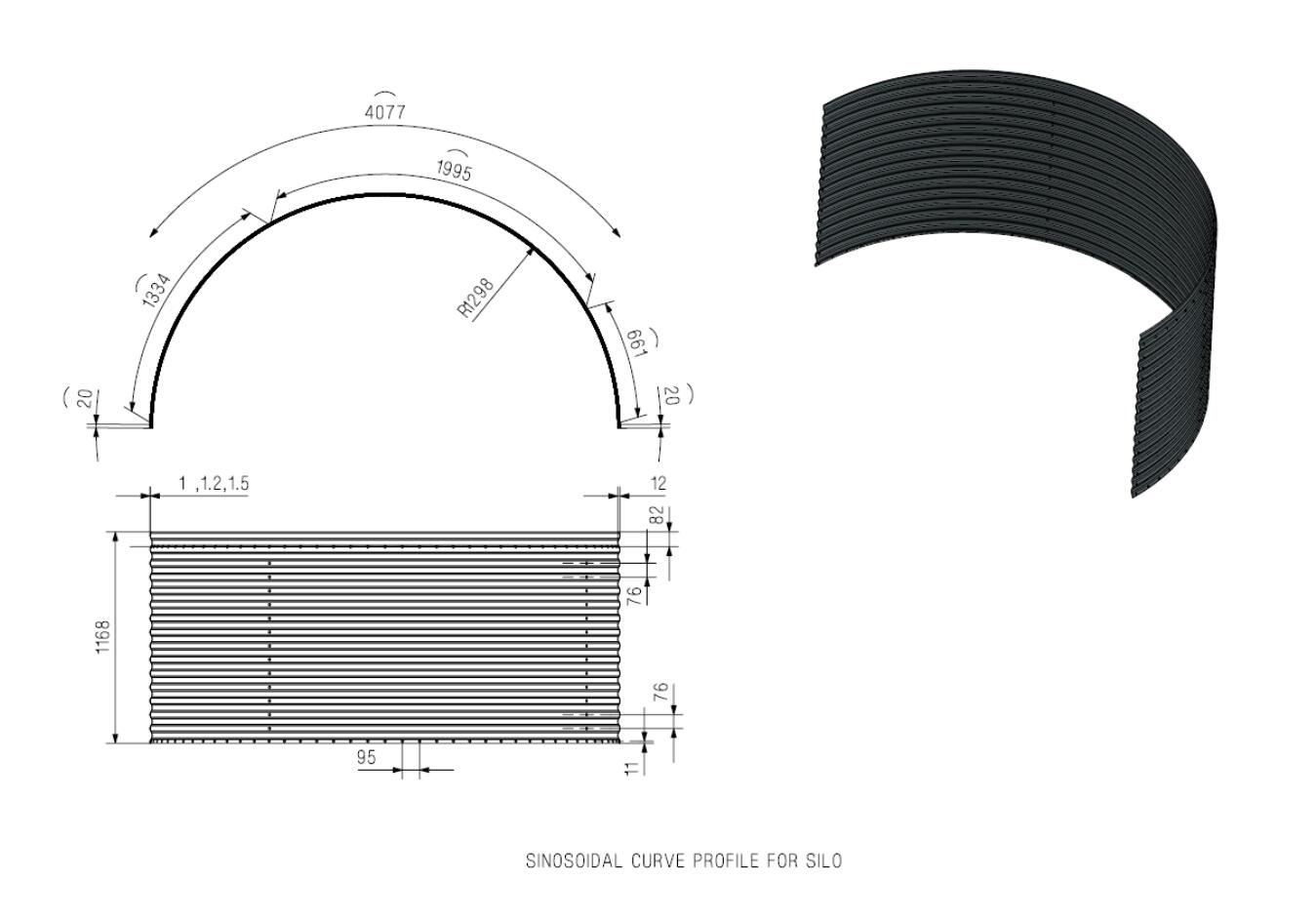

Steel Silo Wall 2.0 - 4.0mm Thickness Corrugated Steel Roll Forming

Machine

Application

Steel silo corrugated sheet, steel silo corrugated panel, silo wall

sheet, silo corrugated wall sheet, silo wall panel, silo corrugated

wall panel, silo side panel, steel corrugated sheet, steel

corrugated wall panel, steel corrugated panel

Working Flow

Loading coil car -> Un-coiler -> guiding device -> feeder

-> leveller -> shear roll former -> hydraulic press ->

curving -> hydraulic cutting -> stacker -> PLC control

| Item | Parameter detail |

| Processing Material | GI and PPGI |

| Material thickness | 0.25-0.8mm |

| Machine frame | 360#H steel, Adopt diagonal line welding, leveling instrument

measurement to make sure the final frame is high-precision |

| Machine siding panel | | plate type | Pillar type(option) | | | | Plate thickness:20mm | Pillar thickness:30mm | | Painting:normal painting | painting:Chroming |

|

| Forming stations | 13-22 stations(according to the profiles) |

| Machine rollers | high grade No.45 forged steel,plated hard chroming with thickness

0.05mm

Processing way:cutting--drilling--CNC lathing--quenching--CNC

lathing--chroming |

| Machine Shaft | φ70-80mm high garde No.45 steel after treatment, |

| Machine spacers | CNC lathing in high-precision |

| Machine bearings | China Haerbin bearing or SKF international bearing(option) |

| Driving system | 1 inch chain or gear box(option) |

| Machine power | 3kw-11kw(according to the profiles) |

| Machine working speed | 8-12m/min or 10-30m/min(option) |

| Machine adjust type | After machine installation, we will test it ourselves, compare with

the profile drawing, the difference is controlled in 0.5mm |

Cutting

| Type | bearing sliding type |

| Blade material | Cr12mov quenching and grinding |

| Frame processing | the whole bottom frame is grinding for high-precision |

| Blade processing | wire-electrode cutting, but the upper balde can not be straight.

this is technology |

| Working | Hydraulic type |

PLC

| Main item | Parameter detail |

| PLC | Delta(standard) or according to your request |

| Inverter | China brand(standard) or according to your request |

| Touch screen | Mcgs(standard) or according to your request |

| Encoder | China brand(standard) or according to your request |

| Voltage/HZ/Phase | 380v/50-60hz/3phase |

Hydraulic pump

| Main Item | Parameter detail |

| Motor | 3kw China brand or according to your request |

| Pump | China brand or according to your request |

| Solenoid valve | China brand or according to your request |

| Cooling system | Cooling fan |

Main product :

Roof roll forming machine

C and Z purlin roll forming machine

Downpipe roll forming machine

Hydraulic decoiler

Light keel roll forming machine6

Bending machine

Shearing machine

slitting machine

Roller shutter door roll forming machine

A). Basic Introduction of Main Components

1). Forming machine: making the material bend and initial

machine-shaping, meanwhile, it will bend the material to the silo

required radius of curvature.

2). Bending machine: it will roll cooperate with good molding

materials bender seaming together

3). Load bearing support: Given the right diameter of silo. Lifting

of the steel silo enclose the top of load bearing support rollers,

it can support the spiral rising silo.

4). Decoiler: Moving steel coils that put on the decoiler, making

steel coils can into forming machine successfully.

5). Join frame: Joining the load bearing support, locking the

required diameter of soil, making the load bearing support stable

working.

B). Main Specifications of Steel Silo Roll Forming Machine

- Suitable material: Galvanized sheet, Zinc Alumina sheet

- Material yield strength: 310Mpa

- Material thickness: 2.5-4.0mm

- Max. Feeding coil width: 1250mm

- Machine working speed: 4-8m//min

- Forming station: approx 18 stations

- Size of roll shaft: Ф120mm

- Roller material: GCr15, quenching HRC 58-62 °

- Total power: approx 180KW

- Power supply: AC440V+/-10%, 50Hz, 3 Phase

- Whole line dimention: about 35M X 4.5M ( L X W )

- Installation height: 4.5m

- Total weith of machine: approx 70 tons

C). Working Flow

Loading coil car -> Uncoiler -> guiding device -> feeder

-> leveller -> shear roll former -> hydraulic press ->

curving -> hydraulic cutting -> stacker -> PLC control

D). Comparison with Common Silo

1. Large capacity

One single-silo capacity is up to 17,000 tons with comprehensive

configurations to meet customers’ different requirements.

2. High accuracy

Complete advanced processing equipment and technology are

introduced from USA to effectively ensure working accuracy and

reduce damage to galvanized layer.

3. Less residues

External installable stiffeners contribute to less grain residues

on silo walls.

4. Detachable and movable

With standardized and modularized production, components and parts

have a high standardization and good interchangeability, thus can

be partially replaced or completely transferred.

E). Our Competitive Advantages

Professional Team Support

High Quality

Reasonable Price

Good aftersale Service

1 Year Warranty

More Than 10 Years Experience

Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled

technicians available.

Q: Once we've bought a machine from you, are you able to supply us

with material?

A: We can assist you in finding the appropriate materials to suit

your machine.

Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers

specifications, using top brand name components.

Q: What size decoiler can you supply us with?

A: From 5-ton decoiler to a 25-ton motorised hydraulic decoiler.

Q: Do you have a warranty on your machines?

A: One year warranty excluding electrical components.

Q: Do you have instruction manuals?

A: We provide you with instruction manuals, electricity layouts,

civil requirements, and machine drawings.

Q: Once a machine arrives at our factory what happens then?

A: We will send you a technician or engineer that will commission

and install your machine, with training for your staff if required

at a separate fee.

Q: What do I need to offload my machine from the container?

A: You are not responsible for the offloading of your machinery,

and it is recommended that you use a reputable rigging company.

Q: My current machine rollers need to be replaced. Would you be able

to assist me?

A: Yes. Send us your profile and specifications then we will

manufacture the rollers for you.

Q: Do we receive any updates while machine is in the manufacturing

process?

A: Yes.Regular updates on progress will be sent to you.