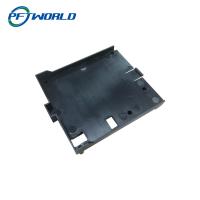

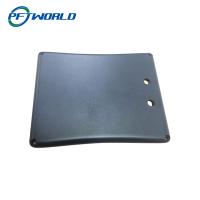

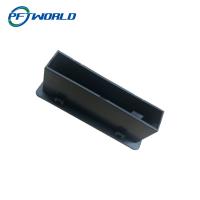

Understanding CNC Machining for Injection Plastic Mold Parts

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that utilizes computer-controlled machines to remove material from a workpiece, creating precise shapes and dimensions. When applied to injection plastic mold parts, CNC machining ensures that molds are crafted with high accuracy, facilitating the efficient production of plastic components.

Advantages of CNC Machining for Custom-Size Injection Plastic Mold Parts

- High Precision and Consistency: CNC machining delivers tight tolerances and uniformity across all parts, ensuring each component meets exact specifications.

- Design Flexibility: Complex geometries and intricate designs can be achieved, allowing for innovative and customized solutions tailored to specific requirements.

- Material Versatility: A wide range of materials, including various thermoplastics, can be machined to produce durable and functional mold parts.

- Rapid Prototyping: Quick turnaround times facilitate the rapid development of prototypes, accelerating product development cycles.

Applications Across Industries

Factory-customized CNC machining for custom-size injection plastic mold parts is integral to various sectors:

- Automotive: Manufacturing of mold parts for components such as dashboards, panels, and connectors.

- Consumer Electronics: Production of mold parts for enclosures, buttons, and connectors.

- Medical Devices: Fabrication of mold parts for instruments, housings, and connectors.

- Packaging: Creation of mold parts for containers, caps, and closures.

Conclusion

Factory-customized CNC machining for custom-size injection plastic mold parts provides manufacturers with the tools to produce high-precision, versatile components tailored to specific needs. By leveraging these advanced machining techniques, industries can achieve superior product quality, reduce lead times, and maintain a competitive edge in the market.

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.