16kw high frequency heating machine frequency copper brazing

welding machine

1. braze woodworking tools induction heating machine:

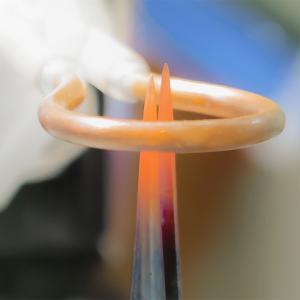

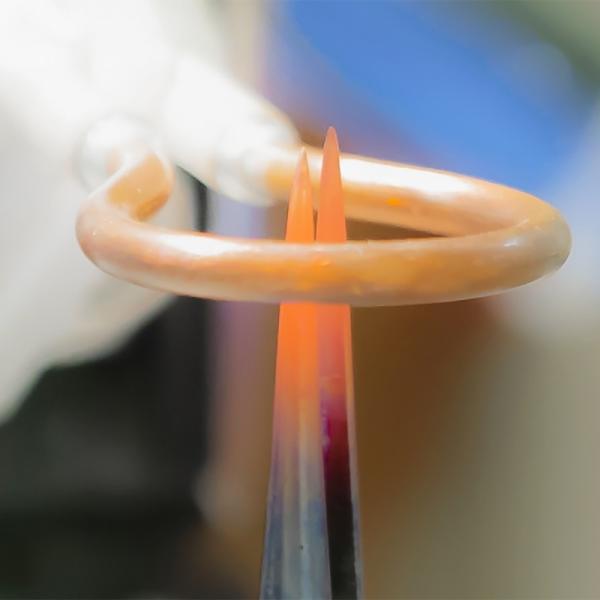

High-frequency induction heating power is used to braze woodworking

tools, and the welding parts are of high quality. Brazing is mainly

by using the brazing filler metal with a lower melting point than

the base metal, placing the brazing filler metal between two metal

parts, and heating it to a temperature higher than the melting

point of the brazing filler metal but lower than the base metal

melting point, so that the brazing filler metal melts and diffuses.

Join two pieces of metal together. In the process of brazing

woodworking tools with high-frequency induction heating power, the

sensor does not need to be in direct contact with the workpiece,

the heating speed is fast, the temperature distribution is uniform,

the surface is free from oxidation and decarburization, the weld is

not easy to produce cracks, and the rate of return to the factory

is low.

2. Application range of Induction Brazing Machine:

high frequency induction heating brazing machine mainly aims to

melt the solder by heating it to a certain temperature for the

purpose of connecting two types of metals of the same material or

different materials.

1. Welding of various hardware cutting tools, such as diamond tool,

abrasive tool, drilling tool, alloy saw blade, hard alloy

cutter, milling cutter, reamer, planning tool and solid center bit.

2. Welding of various hardware mechanical gadget: Silver soldering

and brazing of metals of the same variety or different

varieties, such as hardware toilet and kitchen products,

refrigerating copper fitting, lamp decoration fitting, precision

mold

fitting, hardware handle, eggbeater, alloy steel and steel, steel

and copper as well as copper and copper.

3. Compound pot bottom welding is mainly applicable to the braze

welding of circular, square as well as other irregular plain pot

bottom. It is also applicable to plain braze welding of other

metals.

4. Welding of heating disc of electric hot-water kettle mainly

refers to the braze welding of stainless steel flat base, aluminum

sheet and tubular electric heating elements of various forms.

3. Technical Parameters of LSW-16 Induction Heating Machine:

| Model | LSW-16 |

| Working Voltage | 220V, 50/60HZ |

| Max input power | 16kw |

| Oscillation frequency | 28-40KHZ |

| Duty cycle | 100% |

| Cooling water flow | 20L/Min,0.15-0.2MPa |

| Weight | 25kg |

| Dimension (L*W*H ) | 420*200*360mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating, brazing,melting etc |

4. Main characteristics of LSW-16 Induction Brazing Machine :

1. Adoping MOSFET and IGBT, inverting device, tracking frequency

automatically

2. High frequency, heated quickly, its power consumption is only

20%-30% of electronic tube induction brazing machine and other

heating style.

3. Security and reliability, the equipments have the secure voltage

and it’s secure to operate.

4. Manual, automatic regulating automatically, it can protect

itself from over voltage, over current, lack of water, phase fail,

over hot, etc.

5. It has no open-fire, noise and pollution.

5. Induction Brazing Machine Application:

Heat treatment industry

1 Hot forging aims to fabricate the work pieces of certain

temperature (different materials require different temperatures)

into other shapes through forging press with the help of punch

press, forging machine or other equipments, for instances, hot

extrusion of watch case, watch flan, handle, mold accessory,

kitchen and table ware, art ware, standard part, fastener,

fabricated mechanical part, bronze lock, rivet, steel pin and pin.

2. Hot fitting refers to the connection of different metals or

metals with nonmetals through the heating based on the principle of

hot expansion or hot smelting, for instances, embedded welding of

copper core of computer radiator with aluminum sheet and speaker

web, compound of steel and plastic tube, sealing of aluminum foil

(tooth paste peel), motor rotor and sealing of tubular electric

heating element.

3. Smelting mainly aims to melt the metal into liquid by using the

high temperature, which is mainly applicable to the smelting of

iron, steel, copper, aluminum, zinc as well as various noble

metals.

Forging industry

1. plate heating, bending and forming.

2. standard parts, fasteners through the hot forming.

3. the hardware tools through heat, such as pliers, wrenches and

other heat through hot forming.

4. taper shank drill rod extrusion prospecting.

5. the pipe through the hot forming, such as bends and so on.

Brazing

1. carbide cutting tools welding. Such as turning, milling, cutter

knife.

2. the diamond saw blade welding. Such as diamond saw blade,

abrasive, jagged welding. Exploration drill bit used in welding,

such as word drill, drill welding horns.

3. brass, copper

Smelting

Steel,iron, non-ferrous metals,graphite crucible smelting

6. performance and characteristics of induction heating brazing

machine:

1.Using imported Fuji power components and high-quality components

to ensure high-quality equipment quality

2. Small body weight, high efficiency and energy saving

3. Overcurrent, overvoltage, under water, overheat protection

circuit

4. Exquisite design, 304 stainless steel screws, 304 stainless

steel handlebars, no paint stripping, stripping phenomenon.