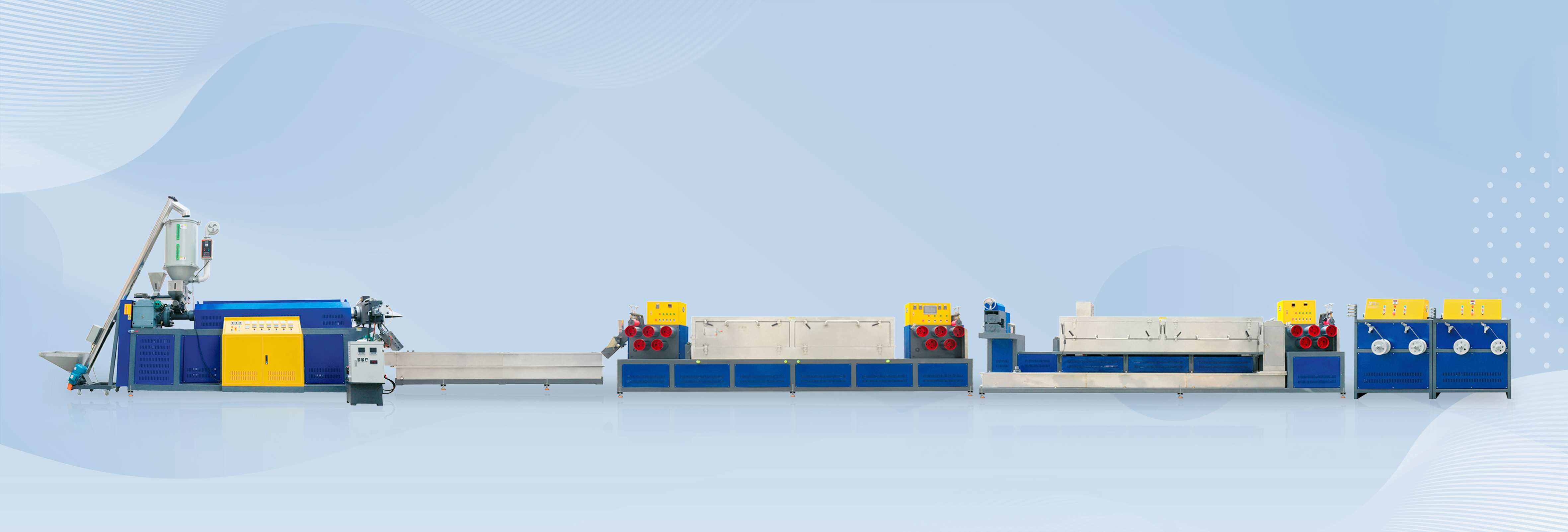

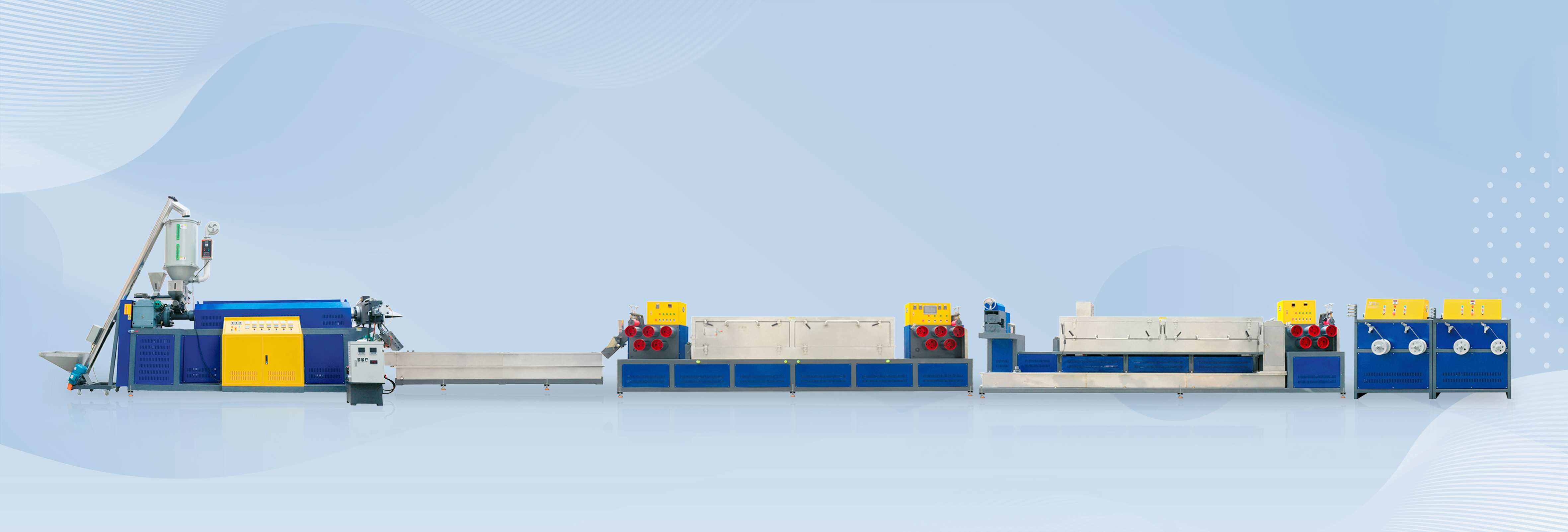

PP Outlet 2 Straps Making Machine Extrusion Line Automatic Packing

Machine

QUICK DETAIL OF PP STRAP MAKING MACHINE

PP strap production line /PP strap manufacturing machine, PP strap

making machine

PP strap with width from 5mm to 19mm can be manufactured by our PP

strap manufacturing machine. we furnish PP strap production

machines with 1, 2, 4 and 6 PP straps extruded.

Name: PP 1 to 2 strapping production line

Model number: JTPP-90

Applicable raw materials: New PP particles, PP recycled materials,

PP crushed materials

Number of screws: 1 Screw

Number of extruded belts: 2

Width range: 5-19mm

Thickness range: 0.4-1.2mm

Production capacity: 200kg/h

Installation size: L38*W2.0*H4.0(m)

| NO. | Component | Feature1 | Feature2 |

| 1 | Drying dehumidifacation crystalization system | Energy efficiency | Feeding devices |

| | Self-adjustment of the system | Rapidity in production shift |

| | Optimal and continuous mixing of the material | No risk of contamination |

| 2 | The three components mixing and feeding unit | Automatic | Increase IV |

| | With automatic ratio mixing system for raw-material additives | Use-100% bottle flakes |

| 3 | extruder | Sevo-extruder can save electric 30% | Low tempreture plastify |

| | High efficiency screw | No deformation at high temperature |

| 4 | Back-flush screen changer | Continuous Back-flush screen changer make the produce non-stop | Full automatic self-cleaning |

| | optimal design of the melt flow way - short melt residence time | low pressure build up - to prevent thermal variations of the melt |

| | no dead spots for fast changes

of material or color | operational reliability and long durability |

| 5 | Melt measuring pump | world's leading elastomer extrusion pumps | over 100 years experience |

| | Protect extrusion equipment | reduce energy consumption |

| | Provide accurate system pressure for the mold | Continuously obtain stable product quality |

| 6 | Cooling tank | Stainless steel/Lifting tension/ | water removal system to maintain tension |

| 7 | Stretching machine | Frequency control | mold tempreture machine control roller surface tempreture |

| 8 | stretching oven | High-performance insulation layer save energy | Maintain the constant tempreture of the strap |

| 9 | Embossing device | High-precision make strap with goof friction | Ensure the accuracy and consistency of strap pattern |

| | Enhance the friction

for strap | Enhance the strength

for strap |

| | Unique technology | World leading high precision standards |

| 10 | winder | Sevo-motor controls winder dispalcement width and distance | Increase the value

of strap |

| | Manual control or computer control is optional | Servo wiring is set by computer according to strap specifications |

| | Automatically adjust the winding tension | The winding curve of the strap reel is perfect |

SPECIFICATION OF STRAPPING MAKING MACHINE

| Output | 150kg/hr | 300kg/hr | 500kg/hr | 800kg/hr |

| Motor Power | 55KW | 110KW | 160KW | 250KW |

| Installation Power | 280KW | 445KW | 635KW | 900KW |

| Speed | 120m/min | 120m/min | 120m/min | 120m/min |

| Overall Size of Machine | 32*4*5m | 46*5*5.5m | 60*6*6m | 60*6*6m |

| Width of Strap | 9-19mm | 9-32mm | 9-32mm | 9-32mm |

| Width Tolerance | ±0.45mm (int. ±0.76mm) |

| Thickness of Strap | 0.55~ 1.27mm | 0.55~1.27mm | 0.55~1.27mm | 0.55~1.27mm |

| Thickness Tolerance | ±0.05mm (int. ±0.06mm) |

| Elongation Rate of Strap | 10~15% |

| Breaking Strength of Strap | < 50kg/mm² |

FEATURES ABOUT PP PACKING MACHINE

(1) Safety and environmental protection:safe for use, not easy to

hurt, according with EU environmental directives, for example ROSH.

(2) Low cost:It is the most cost-effective in new environmentally

friendly packaging materials products.

(3) Easy to use:Suitable for fully automatic balers, manual balers

and other packaging machinery quickly and convenient to use.

(4) Excellent toughness: Between -50 ~ 100 ºC temperature, it is

fully capable of normal use, and maintains excellent flexibility.

(5) Look beautiful: Finish bundled items look beautiful, does not

pollute the items, never rust.

(6) Very good strength: Can provide up to 470 MPA tensile strength

to protect the safety of Strapping.

FAQ ABOUT PP STRAPPING BAND EXTRUSION LINE

1. For PP(polypropylene) strapping band extrusion line

* What about the output of PP strapping band extrusion line? 150kg/hr, 280kg/hr, 500kg/hr.

* What about the size of strap that the PP strap machine can make? Width: 5-25mm; Thickness: 0.35-1.0mm;

* What about the installation power of the PP strap machine? 135kw/155kw/195kw/439kw;

2. For PET(polyester) strapping band extrusion line

* What about the output of PET strapping band extrusion line? 200kg/hr, 400kg/hr, 600kg/hr, 800kg/hr.

* What about the size of strap that the PET strap machine can make?

Width: 9-32mm; Thickness: 0.35-1.2mm;

* What about the installation power of the PET strap machine? 215kw/285kw/352kw/900kw;