Wuxi Jiachen Power Electronic Equipment Co., Ltd. was established

in 2014. The company is committed to exporting the following

products:

1. Various distribution transformer winding cores, such as

S11-100kVA, S13-100kVA; Single phase wound magnetic cores, such as

D9, D10, D11, etc. For pole mounted transformers or pad mounted

transformers, we can also produce three-phase transformer winding

cores; The capacity can range from 10kVA to 2500kVA; For some

customers, we can also design drawings based on your technical

parameters.

2. Full series of circular magnetic cores, C-type magnetic cores,

CD type, and E-type magnetic cores; Widely used in potential

transformers, transformers, transformers, voltage transformers,

current transformers, power transformers, some reactors, and

autotransformers.

3. Various types of series reactors, inductors, DC reactors for

frequency converters, filtering reactors, triangular starting

reactors, starting compensators, autotransformers, low-voltage dry

transformers, current transformers for distribution cabinets,

bushing current transformers, etc. Our company is currently

collaborating with my partners to develop the single core market in

China, and the finished products are operating well among our end

users.

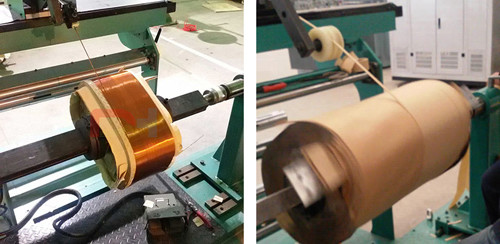

4. Related supporting equipment: vacuum drying equipment; Vacuum

pouring equipment; Annealing furnace; Transformer winding machine,

foil winding machine; Transformer curing furnace; Oven; Epoxy resin

mixing tank; Transformer mold

Wuxi Jiachen is based in China to serve global power, committed to

providing high-quality products and professional problem-solving

solutions. We sincerely welcome you to join us and research new

technologies to improve our product performance, reduce

manufacturing costs, and achieve mutual benefit.