Basic Information

Zhangjiagang City Peony Machinery Co., Ltd., founded as a special

producing enterprise of separating equipment in 2008, is the

well-known manufacturer and service provider of separation and

filtration in China. Peony dedicated to solving the solid-liquid,

liquid-liquid separation problems for clients all over the world

and providing separating and filtering mechanical products with

convenient operation, high efficiency, reliable quality, and

excellent service worldwide. Being a group corporation, Peony has 3

producing bases in China - Zhangjiagang, Nanjing, and Hangzhou

city.

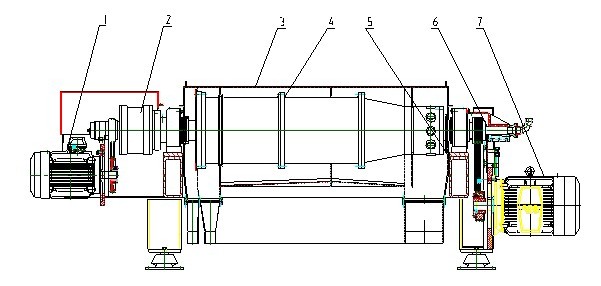

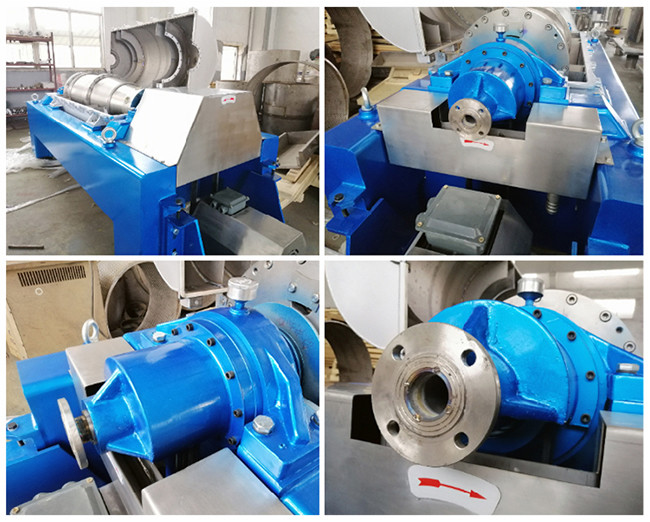

Products

As the professional supplier of separating and filtering equipment,

we produce basket centrifuges, decanters, and disc separators

starch product line, and sell the auxiliary equipment such as

clarify equipment, filters, pumps, etc. These 25 series of more

than 150 products are self-development of Peony and have attained

national patent. Those products and relevant auxiliary equipment

are widely used in chemical, petroleum, pharmacy, mining, food,

beverage industry, and environmental protection.

We own various kinds of inspection and testing facilities with a

value over USD10million, now,16 testing tables,6920 gear testing

center, X-ray detecting machine, high-speed dynamic balancing

machine, ultrasonic flaw detection machines, etc, we are equipped

with complete testing, inspection, analysis control system,

advanced testing machines and simulative working condition test

table and automatic control testing system, which guarantees our

new product research, processing validation, and quality.

We have strongly equipped the robust and precise processing

machines from Germany, Italy, England, and our domestic famous

brand, here, I'd like to list several of them for your reference.

200 Numerical Control Boring and Milling Machine TK6920

160 Numerical Control Boring and Milling Machine TK6916

Italian PAMA Numerical Control Boring and Milling Machine

80T CNC Lathe

40 T CNC Lathe

2.5m Merry Go Round Machine C525E

Z100 Radial Drill

Numerical Controlled Vertical Milling Machine

Underwater Plasma Cutting Center

CNC Machining Center

We harvested great achievement these years, and turnover reaches to

380million RMB in

the year 2013, and we expect to carry out 500million RMB in 2015.

Welcome all who are engaged in the separation and filtration to

work with us, and we are also looking for qualified world wide

agents to provide better service and deep marketing.

Worldwide Network

Our products have spread all over the world and are applied over 35

countries and regions, for example, America, Germany, Italy,

Sweden, Canada, Singapore, Australia, Brazil, Russia, India, Middle

East, and Southeast Asia, etc. To provide flexible and qualified

technical service to resolve any maintenance issue in the shortest

time possible, now we have established agents in many countries

such as Brazil, Colombia, Latin America, Bangladesh, Southeast

Asia, etc.

Society Reward

Peony is devoting into the charity activity, we are

subsidizing some poor students to finish the school and are trying

to set up some primary to feedback the society, hereby,

we appeal to all people to enter into the charity activity,

technical innovation changes the world, love embraces the world!