QINGDAO GORLD INDUSTRIES CO., LTD.

Qingdao GORLD Industries Co., Ltd. (GORLD MACHINERY) belongs

to GORLD INDUSTRIES CO., LTD. We are a woodworking machinery, metal

finishing machinery, plastic machinery, plywood, MDF board,

particle board, furniture, far infrared sauna room manufacturer and

supplier. Our factories are located in China. We manufacture and

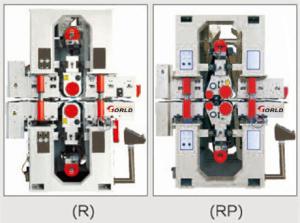

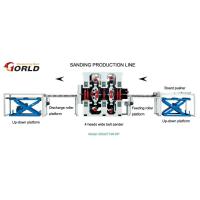

market a wide variety of wide belt sanders, curved surface brush

sanding machine, planer sander, edge trimming saw/ DD saw, sliding

table saw machine, panel saw, band saw, circular saw, multiple

blade saw, woodworking thicknesser, double-side planer, 4-sides

moulder, cold press machine, hot press machine, drilling machine,

CNC carving machine, edge banding machine, knife grinding machine,

finger-joint machine, and dust collector, which are extensively

utilized in electronic, electrical equipment, furniture, wood

processing, construction decoration and other industries.

We understand that only high quality products and service will earn

us a good reputation with clients. With more than 10 years of

experience and product development, we are able to provide products

which follow the ISO9001:2008 international quality management

system. We carefully select only the best raw materials and

equipment with which to manufacture our belt sander and wood

cutting saw. Our production equipment is acquired from South

Korea’s Hyundai-Kia Machine Corporation. Using these machines,

maintaining a strict regimen of quality control and making our

products CE certified, we have shipped GORLD products to satisfied

customers all over the world. Our cutting machine, metal surface

processing machine and other woodworking machinery are well

received by customers from Europe, Russia, Canada, USA, Spain,

Hungary, Ukraine, Bulgaria, Turkey, Iran, UAE, Israel, UZ, HZ,

Mongolia, Pakistan, India, Sri Lanka, Thailand, Vietnam, Cambodia,

Malaysia, Indonesia, Philippines, Japan, Korea, Australia, New

Zealand, Fiji, Bengal, Mexico, Peru, Argentina, Brazil, Egypt,

Ecuador, Ethiopia, Sudan, S. Africa, Nigeria and more, and our

export volume is increasing.

GORLD MACHINERY is located in Qingdao City, Shandong Province,

China. Our factory covers an area of approximately 35,000㎡. It

is about 15 miles from us to Qingdao Port in the Qingdao economic

development zone, 15 miles to Qingdao Jiaodong International

Airport and Jiaozhoubei Railway Station. Our proximity to so many

modes of transportation makes it easy to offer lowcost shipping to

countries all over the world.