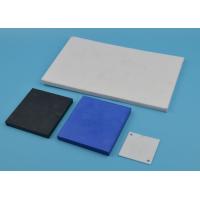

Non Conductive Round Zirconia Alumina Ceramic Block / Beads /

Insulator

keywords: ceramic guide block

| - Product Name: | Alumina Ceramic Block |

| - Typical Characteristics: | 1. High Hardness And Wear Resistance

2. Good Thermal Stability

3. Excellent Dielectric Properties 4. Low Loss Tangent |

| - Typical Applications: | 1. Seal Ring 2. Electrical Insulator 3. Thermocouple Tubes 4. Ballistic Armour 5. Electronic Substrate 6. Grinding Media 7. Wear Components 8. Oxygen Sensors |

Advantage of High Temperature 99% Al2O3 Alumina Ceramic Block

1. Refractory, High Temperature Resistance, Maximum Used

Temperature: 1800 ºC (3272ºF)...

2. Hardness Strength Up To Mohs 9.0; HRA 80-90, Wear Resistance

wear rate 0.68 mm3·m-2·h-1....

3. High Voltage, Good Insulation Performance ,Electrical

Resistivity Up To 10∧14 Ohm.Cm...

4. High Polished Surface Up To Rz0.8(Ra0.1) ...

5. Superior Mechanical Strength, Max 10 MPa.m1/2 Fracture

toughness,

6. Pressure Resistance, Max 2300MPa compressive strength...

7. Anti-High Corrosion Resistance, Such As Acid Alkali

Resistance...

8. Long Service Life...

9. Other excellent property

Detailed Description of High Temperature 99% Al2O3 Alumina Ceramic

Block

Technical Data

| Al2O3 Purity (%) | Density (g/cm3) | Bending Strength (Mpa) | Expansion (X10-6/ºC) (25-800ºC) | Thermal Conductivity (W/(m.R)) | Dielectric Strength (kv/mm) | Max Working Temperature (ºC) | Water Absorption (%) |

| 95 | 3.60 | 364 | 7.6 | 20 | 11 | 1500 | <0.2 |

| 99.7 | 3.90 | 450 | 8.0 | 35 | 12 | 1800 | <0.1

|

Produce and machining

We can produce different sizes and shapes of the sheets for

specific applications to different custom products.Such as

drilling, polishing, stripes, concave and convex, screw holes,

metal parts position and so on

1. Can Be Custom By Drawing Or The Parameter

2.Can Be Offer a Samples Within 1--10 Qty

3. The Shipping Time Of The Samples Within 2days

4. Quick Delivery Via Fedex,Dhl,Ups,Tnt Etc.

For more informations (the price,payment etc), Please contact us or email: admin@cerampart.com

Application

Ceramic block can be used for a device or equipment in the special

environment such as Power isolation, high temperature protection,

durable wear, high and low temperature impact etc...and for the

different device should be requiry different ceramic block shapes,

like: some device need the round sheet be machining 8 hole to

fasten to the box.

Properties of Alumina and Zirconia Ceramic :

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.92 | 5.95-6.0g/cm³ |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness HV | MPa | 1400 | 1650 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 310 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 | >1015 |

| Max use temperature | °C | 1500 | 1750 | 1050 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 16 | 22 | / |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 252 |

Company Introduction:

We ( Dongguan Mingrui Ceramic Technology Co., Ltd ) are a

professional manufacturer specialized

in R&D, manufacturing and selling customized all kinds of high

precision zirconia and alumina ceramic parts . Our main products

include ceramic rod , ceramic tube, ceramic plunger, ceramic valve,

ceramic plate, ceramic shaft and bearing , ceramic nozzle etc ,

which are mainly used in industrial fields of Machinery,

Petrochemical oil and gas, Valves, Automotive, Food Processing,

Fluid Handling, Process Control, Thermal Processing, Aerospace,

Defense, Eletronic and Electrical, Textile, Mechanical,

Engineering, Mineral Processing, etc.

We have a full service include mold design and development ,

ceramic forming , precision machining

and precision detection technology. We have achieved great

successes in particular requirements

which is based on cooperating with Tsinghua University and getting

rich experience by our professional technical engineer teams . Our

factory have an unique technical called mirror polishing which

improve

our products more smooth , bright than other competitors.

Related products more photos:

1. What kind of industry ceramics do you have ?

We specialized in 95% 97% 99% alumina ceramic and zirconia ceramic

parts .

2. What kind of molding method do can you supply ?

Dry Pressing , isostatic pressing , grouting , hot-chamber die

casting , tape casting , injection molding, etc, injection molding

and isostatic molding is the most commonly used.

3.What stabilizer do you use when processing ?

Yttria stabilizer is the most commonly used in our industrial

ceramic parts.

4.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to

the product complexity .

5.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but

paypal and western union only for small -sum payment.